Logistics in 2026: Operating at a Structural Crossroads

In 2026, the global logistics and warehousing industry entered a structurally different phase. The assumptions that governed supply chains for decades, including stable trade rules, cost-first optimization, and predictable global flows, no longer hold.

The operating environment is now defined by policy volatility, regional realignment, and an increasing gap between planning intent and operational reality. For senior leadership, the performance criteria have shifted. Efficiency remains important, but it is no longer sufficient on its own. Agility, resilience, and structural independence now determine long-term competitiveness.

This shift is structural.

From Optimization to Structure

Global Standardization | Regional Divergence

Just-in-Time | Inventory Optionality

Manual Planning | AI-mediated Planning

Static Routes | Simulated Rerouting

Efficiency Metrics | Resilience Metrics

1. The Protectionist Pivot: Mastering Tariff Agility

For most organizations, trade policy has become an active source of operational instability, directly affecting pricing, contracts, and inventory decisions.

This instability is not theoretical. Since 2020, approximately 18,000 discriminatory trade measures have been implemented globally. In the first ten months of 2025 alone, 2,500 new measures were introduced, according to Global Trade Alert. The cumulative effect has been rapid fragmentation of previously stable trade corridors.

The financial impact is direct. Trade-weighted average tariffs on manufacturing rose from 1.9 percent in 2024 to nearly 5 percent in 2025, forcing many organizations to revise landed-cost calculations multiple times within a single year. Cost certainty, once assumed, is now conditional.

Because cost models can no longer be locked in with confidence, executive strategy is shifting away from pure Just-in-Time models toward regionally distributed inventory and sourcing structures. This objective is operational optionality.

Bonded warehouses and Foreign Trade Zones are seeing renewed strategic importance. By deferring duties until the point of sale or domestic entry, companies reduce capital lock-up and retain flexibility in markets where tariff structures change frequently. In an environment of higher interest rates and tighter working capital, this approach provides measurable financial benefit.

Tariff agility is becoming a baseline requirement for operating at scale.

Baseline Operating Assumptions for 2026

Regional strategies will diverge rather than converge

Tariff exposure will remain difficult to lock over the long term

Disruption response will need to be pre-modeled

Human-only planning will fall behind system speed

2. A World of Fragments: The 2026 Regional Outlook

One of the central challenges for logistics leaders in 2026 is that a single global strategy no longer works across regions. Each major region now operates under distinct cost structures, regulatory demands, and capacity constraints, forcing organizations to manage fragmentation inside their own networks.

The result is coordination complexity, where decisions optimized for one region often degrade performance in another.

North America

North America has consolidated its position as a reshoring and nearshoring hub. By 2026, 69 percent of supply chains serving U.S. customers are located within the Americas, according to Prologis Research.

Warehouse utilization has reached 85.5 percent, creating capacity constraints that accelerate investment in automation. Automated Storage and Retrieval Systems are no longer viewed as efficiency upgrades but as necessary responses to labor availability and throughput requirements.

Asia-Pacific

Asia-Pacific continues to function as both a manufacturing base and a consumption market, but production is more geographically distributed than in previous cycles. Manufacturing shifts to Vietnam, Thailand, and Indonesia have driven demand for high-density and vertically optimized warehousing.

India stands out within the region. With projected 9.2 percent CAGR through 2026, growth is being driven by large-scale infrastructure upgrades, including freight corridors, expressways, port digitization, and tax-driven supply chain consolidation.

Europe

In Europe, regulatory pressure has reshaped logistics priorities. From January 2026, the EU Emissions Trading System fully applies to maritime transport, requiring carriers to account for 100 percent of emissions.

This affects routing decisions, carrier selection, and total transport cost structures. At the same time, logistics real estate remains constrained. Vacancy rates in core hubs such as Germany remain below 5 percent, limiting expansion flexibility despite increasing compliance requirements.

Latin America and Africa

Latin America and Africa are gaining importance as manufacturing and transit regions rather than peripheral markets. Manufacturing exports now account for 40 percent of Mexico’s GDP, reinforcing its role as a critical nearshoring destination.

In Africa, the adoption of digital customs platforms has materially reduced clearance times. Early adopters, including Egypt and South Africa, have recorded 30 to 50 percent improvements, improving reliability in cross-border movement.

Oceania

Australia and New Zealand are prioritizing supply chain security through domestic capability building. Investments are focused on local manufacturing buffers, strategic inventory positioning, and technology-enabled maritime monitoring to protect long trade lanes with limited redundancy.

What Often Goes Unaddressed

Many organizations continue to treat trade policy, regional operations, geopolitical risk, and technology as separate planning domains. In practice, these factors now interact continuously. Decisions made in isolation increasingly compound risk rather than reduce it.

3. Geopolitics as a Meta-Risk

By 2026, geopolitical disruptions routinely invalidate logistics plans that were operationally sound only weeks earlier. Energy access, regulatory alignment, and geographic proximity to demand centers now play a decisive role in network design.

This has led to a shift toward what many organizations describe as a “flight to quality,” favoring locations with reliable infrastructure, stable governance, and predictable energy supply.

Critical chokepoints such as the Suez and Panama canals continue to operate, but their reliability is no longer taken for granted. To address this exposure, many organizations are implementing digital twins of their logistics networks. These systems support real-time simulation of route closures and capacity disruptions with rerouting decisions occurring within minutes rather than hours.

The practical outcome is a move away from reactive crisis management toward pre-modeled response scenarios embedded within planning systems.

An Operational Implication

If a critical chokepoint were disrupted for ten days, could routes be recalculated without executive escalation?

If demand shifted regions mid-year, would planning systems adapt without manual overrides?

If the answer to any of these is no, the constraint is structural.

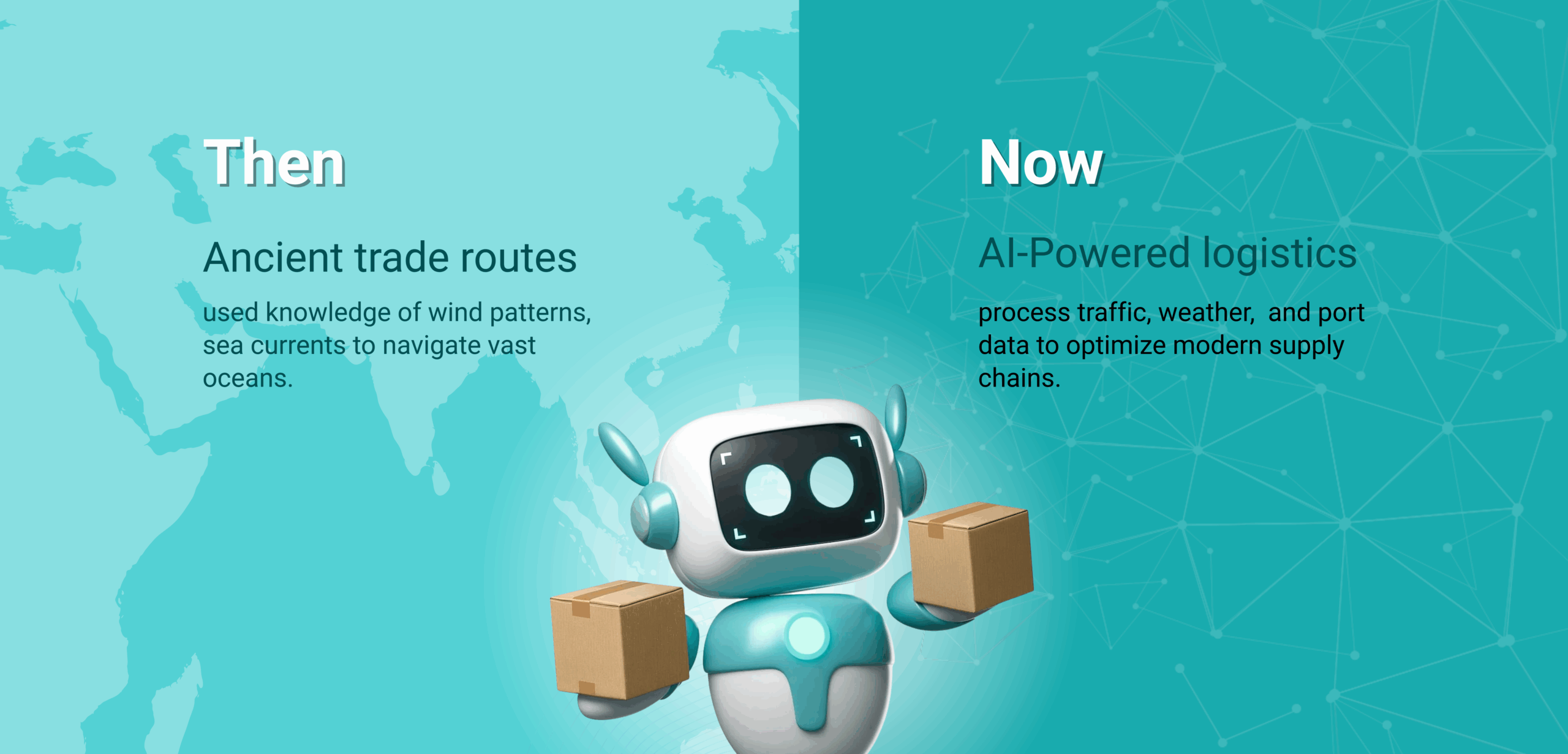

4. From Human-Centered to AI-Mediated Operations

Technology now functions as the primary decision framework within logistics operations, rather than a supporting layer. Traditional human-centered planning models are no longer able to keep pace with the volume, speed, and interdependence of logistics decisions.

As a result, by 2026, 73 percent of executives expect their supply chains to rely heavily on AI-driven systems. Already, 24 percent of organizations report that AI-based planning systems influence daily operational decisions.

Spending patterns reflect this shift. Nearly 40 percent of freight forwarders and 3PLs are allocating more than 25 percent of their 2026 technology budgets to autonomous or semi-autonomous systems.

Measured outcomes are consistent across early adopters. These organizations report approximately 15 percent reductions in logistics costs and 35 percent improvements in inventory management performance. Beyond cost, AI adoption is changing planning timelines. Decision-making is becoming continuous rather than periodic, driven by real-time data rather than static forecasts.

Human expertise has not been replaced. Its role has changed. Leadership focus is moving from operational resolution toward governance, exception design, and system oversight.

What Has Quietly Become Non-Negotiable

Region-specific operating models

Pre-modeled disruption scenarios

AI-mediated planning at scale

Infrastructure decisions aligned to policy risk

Leadership at the Structural Level

After years of volatility, policy shock, and planning breakdowns, the defining characteristic of logistics leadership in 2026 is structural readiness.

Organizations that perform well are not necessarily faster or larger. They are designed to operate under volatility without repeated reconfiguration. They have regional flexibility, tariff-sensitive infrastructure, geopolitical risk models, and AI-mediated planning rooted into daily operations.

The industry has moved beyond incremental optimization. Structural design now determines resilience, cost stability, and responsiveness.

For leadership teams, the challenge is no longer whether change is needed, but whether current operating structures are capable of sustaining performance under permanently altered conditions.