DISTRIBUTION MANAGEMENT SYSTEM

1. Major trends that distributors must address :

Flourishing in augmented economy : Starting from e-trading and new retail business trend like multiple e-commerce websites, mobile applications, chatting applications, social media, customers want all of these in order to add the traditional- in – person, mobile and shipping services. E.G: A customer if wants to buy a product using internet in the evening, picks it up at the branch office next morning and can return it to the retail outlet. Distributors can introduce omni channel and van selling techniques, one that supports wide rage of supply channels and mobility devices to cater local areas and small enterprises.

Re-structuring the duty of the distributors : Highlighting themselves is an important strategy in such markets and distributors must have to implement some innovative and easy way to serve customers efficiently. Some distributors may diversify or expand their services like delivery at shop, online ordering , online pricing system, checking inventory in mobile phone to manage traditional break bulk system. For example, a food distributor might develop a mobile app that allows chefs to track inventory and automate the reordering of supplies to meet par levels.

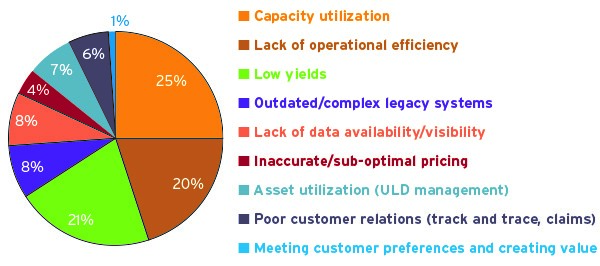

Inspecting & Optimizing : Most distributors must have immediate access to more data than any other player in the value chain. With the right business intelligence, analytics, and reporting tools, distributors can quickly gain new insight into not only their operations but also the impact of customer interactions on business results. For example, distributors can use data to understand the true costs and profitability of each customer. With this insight, companies can adjust their processes to increase profitability.

Hold on to the new developed trends : Distributors must be prepared to quickly adopt effective new technologies. Some distributors want to use the technology to automate warehouse for instant out scan and delivery. Modern distributors are likely to implement augmented reality to have a knowledge of single inch information in the warehouse. Van selling- instant order taking, one hour delivery and instant invoicing is a great change in distribution industry.

2. Challenging factors :

Few visible challenging factors, customer relation system, awaking customers, being far from market, organizational culture, being more responsive for customers, achieving brand promise and also recognizing various life style, understanding customers needs, these information acquisition and local brands existing in the market also could be a good threat and wasting time.

3. Technology is driving the trends in the distribution market :

E-commerce is piling up : Distributors have growing interest in building a stronger e-commerce platform for their businesses. Almost 96 % of distributors have upgraded their website. E-commerce functionality is one of the top line up distributors want to step into. The interest is widespread among both small and large distributors.

Mobile is a game-changer : Mobile has changed how salespeople do their jobs and how they access information. Distributors are taking advantage of this trend not only to provide another channel for purchasing but also to grow mind share with customers. Mostly manufacturers are likely to deliver goods as early as possible and mobile has become revolutionary in this aspect.

Analytics is a step ahead : Advancing technology is allowing distributors to process data faster than ever before, resulting in the ability to track trends and be more strategic in applying sales resources. There’s a reality gap in what distributors want to do and what they are doing when it comes to the Big Data trend.