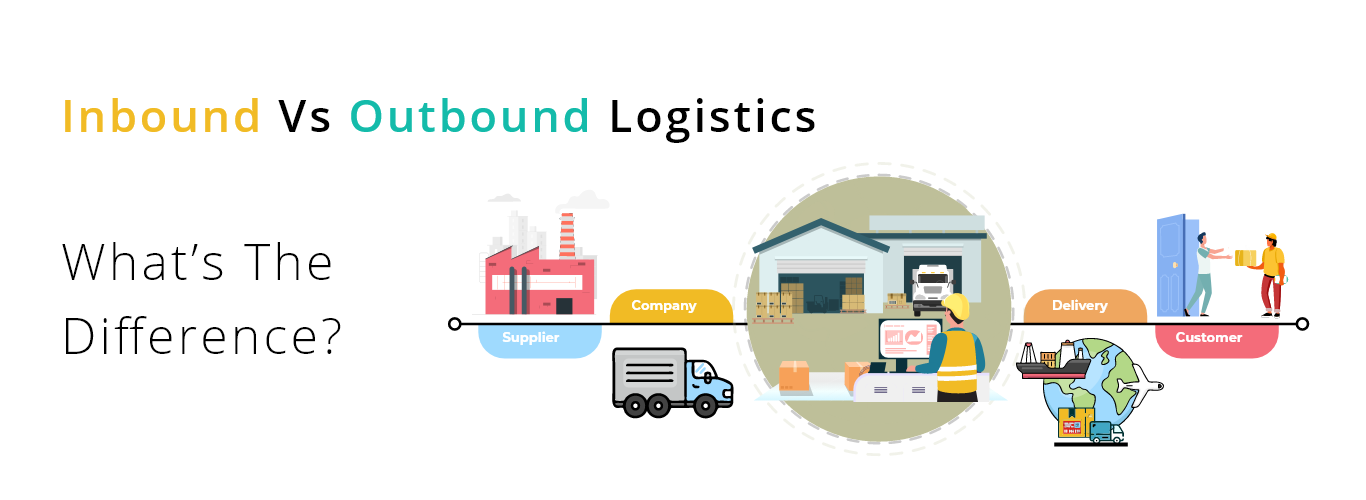

Inbound and outbound logistics are essential components of the supply chain management process, each focusing on a different aspect of the movement of goods within a business or organisation:

1. Inbound Logistics:

Inbound logistics, also known as inbound transportation or inbound supply chain, refers to the processes involved in managing and controlling the movement of raw materials, components, and other goods from suppliers or vendors to a company’s production or distribution facilities.

The primary goals of inbound logistics are to ensure a timely and efficient flow of materials, reduce transportation costs, manage inventory, and maintain good relationships with suppliers.

Activities in inbound logistics may include procurement, vendor management, transportation scheduling, receiving, quality control, and inventory management.

2. Outbound Logistics:

Outbound logistics, also known as outbound transportation or outbound supply chain, pertains to the processes of moving finished products, goods, or services from a company’s production or distribution facilities to its customers or end-users.

The main objectives of outbound logistics are to deliver products to customers on time, minimise transportation costs, manage order fulfilment, and provide excellent customer service.

Outbound logistics activities include order processing, order picking and packing, distribution, transportation planning, and delivery to customers or retail locations.

Outbound vs. inbound logistics

Outbound and inbound logistics serve a similar purpose in that they help measure a company’s supply and demand needs and any data associated with moving or receiving materials and goods.

Key Differences Between Inbound Logistics and Outbound Logistics

The primary differences between inbound logistics and outbound logistics are given hereunder:

1. Inbound Logistics refers to the buying, storage and dissemination of the incoming goods, to the production unit. On the contrary, outbound logistics implies the transmission, selection, packaging and transportation of final goods to the consumers.

2. Inbound logistics, is all about sourcing and receiving of material and its management, in the organisation. Conversely, outbound logistics is mainly concerned with the customer service and distribution channels.

3.The inbound logistics is oriented towards utilisation of resources and raw materials, within the manufacturing or assembly plant. As against this, outbound logistics stresses on the outflow of finished goods or products from the firm to the final consumer.

4. In inbound logistics, the interaction takes place between the supplier and the company. Unlike outbound logistics, in which the interaction is between the company and the ultimate consumer.

Examples of Inbound and Outbound Logistics

Inbound and outbound logistics are two critical components of the supply chain management process. They deal with the movement of goods, materials, and information into and out of a company’s operations. Here are examples of each:

Inbound Logistics:

1. Raw Material Procurement:

When a manufacturing company purchases raw materials like steel, plastic, or chemicals from suppliers to be used in its production process, it’s an example of inbound logistics.

2. Supplier Management:

Managing relationships with suppliers, ensuring timely deliveries, negotiating terms, and optimising the supply chain for efficient inbound material flow.

3. Receiving and Inspection:

Receiving, inspecting, and verifying the quality of incoming materials or products before they are used in production or storage.

4. Warehousing:

Storing incoming materials and components in a warehouse or distribution centre until they are needed in the manufacturing process

5. Inventory Management:

Managing inventory levels, safety stock, and reorder points to ensure a smooth flow of materials into the production process while minimising excess inventory.

Outbound Logistics:

1. Order Fulfilment:

Picking, packing, and shipping products to customers or distribution centres after receiving orders, especially in e-commerce and retail industries.

2. Distribution:

Managing the transportation and distribution of finished products to various locations, such as retail stores, wholesalers, or end customers.

3. Transportation:

Coordinating the transportation of finished goods using various methods, including trucks, ships, planes, or trains, to reach their destination.

4. Customer Service:

Providing post-sales support, handling returns, and managing customer inquiries related to product delivery and quality.

5. Reverse Logistics:

Handling the return and disposal of defective or unsold products, recycling, or refurbishing, and ensuring compliance with environmental regulations.

6.Packaging:

Designing and using suitable packaging for products to protect them during transportation and to make them attractive to customers.

Conclusion

Logistics is an integral part of the supply chain management, which results in the timely delivery of the goods and materials to the final destination. It aims at providing the right goods, at given time, in desired quantity and condition, at proper place and price.

Inbound logistics includes all the activities that are concerned with order placement to the suppliers. On the other hand, outbound logistics covers all those activities that involve dealing or trading in products produced by the company.

The supply chain efficiency relies on well-managed inbound and outbound logistics. Any negligence can give companies a tough time in product sourcing and delivery to the end-users. As inbound and outbound logistics are two key components of the supply chain, you need to focus on optimising them for a better experience.

Understanding the distribution channels and every step of the process is essential, but you can’t go far without using the right tools. Therefore, invest in the LogixPlatform that eases the burden of outbound and inbound logistics management.